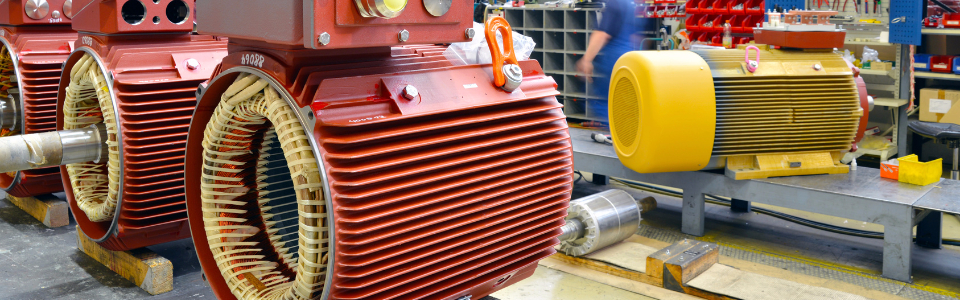

Polyglas® banding tapes have the following fields of application:

· Rotor and comutator banding (main use)

· Transformer core banding

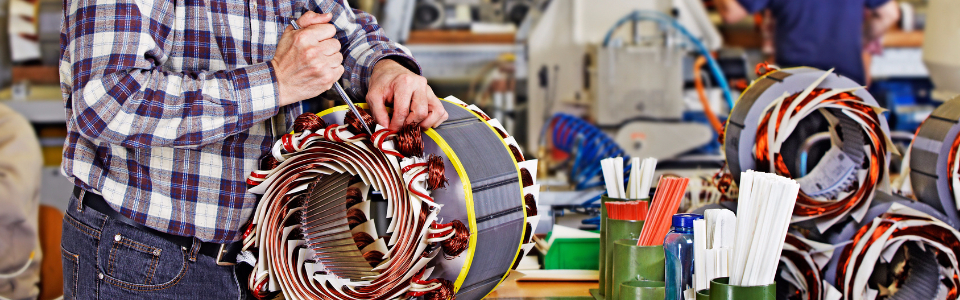

· Bracing end windings of form- wound stators

Resin bonded glass yarn banding tapes are wound around the outside of the coil ends of heavy duty direct current motor armatures to act as a mechanical restraining band. They secure the armature from the effects of large centrifugal forces which are normally experienced by such motors.

Banding tapes have largely replaced steel wires in performing this function; they provide equivalent mechanical strength, whilst solving the problems of using a conducting wire:

- Electrical conductivity which makes essential the use of an underlying electrical insulation to avoid shorting and flashover.

- The generation of eddy currents which cause local overheating and in turn contribute to fatigue and welding between adjacent end turns.

-Relatively high material and application cost.

-Susceptibility to corrosion on exposure to moisture with resulting mechanical failure.

The following products for banding applications are available:

Polyglas® P30 is a basic class F (155 °C) banding tape, used for banding rotors, overhangs, collectors and dry and oil filled transformer.

Polyglas® H200 is a standard class H (200 °C) moisture resistant banding tape, used mainly for banding rotors and overhangs.

Polyglas® H220 is an improved class C (220 °C) moisture resistant banding tape, used mainly for banding traction rotors, collectors and overhangs.

Polyglas® K220 is the ultimate class C (220 °C) moisture resistant banding tape, Kevlar® based, used mainly for banding permanent magnets rotors, high speed starters and whenever steep operative cycles or reduced spaces are required.

Polyglas K-220, 180m roll

Introducing POLYGLAS K220

25 years after introducing, as a true innovation, its famous Moisture Resistant Polyglas H200. VonRoll is moving one step beyond by putting on the market its new Polyglas K220. This new material is no more than a class C, moisture resistant, extra strong B-Stage banding tape. It combines the best of an outstanding thermal resistant synthetic resin, a selection of reinforcement fibres offering extremely high tensile strength, and a well mastered manufacturing process that guarantees consistent quality over the year, long shelf life, high wetting power of the fibres for your perfect application.

Polyglas K220, when properly processed, is made to offer a tensile strength that is twice bigger than anyone of the best market glass reinforced banding tapes. It is then a material of choice for designers of electrical rotating machines who are thinking of increased rotational speed, higher inertia, lower space, increased safety factors, etc.

Polyglas K220, like any B-Stage tape is to be processed with a suitable tensioning device. As it 100% insulating, it may advantageously replace carbon fibres, pure Kevlar tapes, stainless steel banding, and even stainless steel retaining rings.

Whether you are designing or repairing permanent magnet rotors, slip ring motors, traction motors, wind mill generators, high speed generators, turbine generators, brushless AC motors or any other rotating machines that needs a critical banding system.

DATA SHEETS POLYGLAS®

P30/H200/H220/K220

Main Characteristics

P30 | H200 | H220 | K220 | Test Norm | ||

Thickness | mm | 0.30±0.03 | 0.30±0.03 | 0.30±0.03 | 0.33±0.03 | IEC 60371-2 |

Total weight | g/m² | 600±60 | 600±60 | 600±60 | 600±60 | IEC 60371-2 |

Volatile content | % | 0,9±0,5 | 0,9±0,5 | 0,9±0,5 | 0,9±0,5 | ASTM D 2369-A |

Resin content* | % | 26±2 | 26±2 | 26±2 | 26±2 | ASTM 2408-6.2.2 |

Number of yarns/cm | n | 30±1 | 30±1 | 30±1 | 26±1 | ASTM D 902 |

Minimal tensile strength | N/cm | 2000 | 2000 | 2000 | 4000 | IEC 60934-2 |

Pull in banding | N/cm | ≤1000 | ≤1000 | ≤1000 | ≤2000 | |

*content of 22% on request

Shelf life as supplied | ||||||

at 10° C | Months | 24 | 24 | 24 | 24 | Before removing cool material from plastics bag let the tape reach room temperature |

at 15° C | Months | 18 | 18 | 18 | 18 | |

at 20° C | Months | 12 | 12 | 12 | 12 | |

at 30° C | Months | 8 | 8 | 8 | 8 | |

Characteristics after application and curing | P30 | H200 | H220 | K220 | Test Norm | |

Thermal Class | °C | 155 (F) | 200 (H+) | 220 (C) | 220 (C) | IEC 60085 |

Cured Thickness | mm | 0.25 ±0.02 | 0.25 ±0.02 | 0.25 ±0.02 | 0.31 ±0.02 | |

Minimal Tensile Strength referred to | ||||||

one tape layer at 20°C | N/cm | 2500 | 2500 | 2500 | 3500 | |

one tape layer at thermal class | N/cm | 1800 | 1800 | 1800 | 2500 | |

Modulus of Elasticity | ||||||

at 20°C | N/mm² | 62000 | 62000 | 62000 | 80000 | |

at thermal class | N/mm² | 50500 | 52000 | 50500 | 65000 | |

Elongation at break at 20°C | % | 1.6 | 1.6 | 1.6 | 0.6 | |

Elongation at break at thermal class | % | 1.4 | 1.4 | 1.4 | 0.5 | |

Breaking load at -35°C | N/cm | 2700 | 2700 | 2700 | 2700 | |

Coefficient of Linear Expansion | 1/°C | 6,5 E-6 | 6,5 E-6 | 6,5 E-6 | 6,5 E-6 | |

Thermal conductivity | W(m°C) | 0,53 | 0,53 | 0,53 | ||